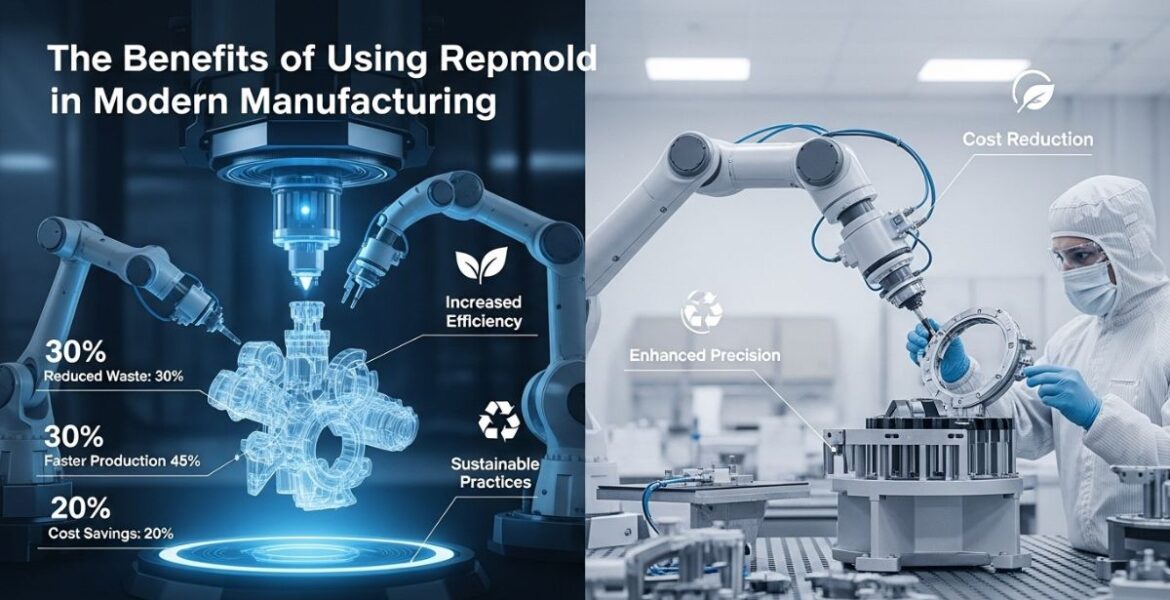

The Benefits of Using repmold in Modern Manufacturing

In the ever-evolving landscape of modern manufacturing, innovation is key to staying competitive. Enter repmold, a material that’s quickly gaining traction in various industries. With its unique properties and versatility, repmold is revolutionizing the way products are designed and produced. Imagine a solution that not only enhances efficiency but also promotes sustainability—sounds appealing, right? From automotive parts to consumer goods, this cutting-edge material has found its place as an indispensable tool for manufacturers looking to elevate their production processes. Let’s dive into the benefits of using repmold and discover why it’s becoming a go-to choice for savvy manufacturers everywhere.

Advantages of using repmold over traditional manufacturing materials

Repmold stands out for its versatility. Unlike traditional materials, it can be easily molded into complex shapes. This flexibility allows manufacturers to create innovative designs that were once difficult or impossible.

Another significant advantage is weight reduction. RepMold products are typically lighter than their metal counterparts. This feature enhances overall efficiency, particularly in industries like automotive and aerospace.

Durability is another key factor. RepMold boasts resistance to chemicals and environmental factors, ensuring longevity without the common wear issues associated with metals or plastics.

Moreover, the speed of production is remarkable. With reduced cycle times during molding processes, companies can ramp up output without sacrificing quality.

This combination of traits makes repmold a game-changer in modern manufacturing, pushing boundaries while maintaining reliability across various applications.

Cost-effectiveness and sustainability of repmold

Repmold stands out as a cost-effective alternative in modern manufacturing. Its unique properties allow for higher efficiency during production, which translates to lower costs over time.

The material is lightweight yet durable, reducing transportation expenses and energy consumption. Longer-lasting products mean fewer replacements, further enhancing long-term savings.

Sustainability is another compelling aspect of repmold. It can be produced using recycled materials, minimizing waste and environmental impact. Many companies are shifting towards eco-friendly practices, making repmold an attractive option.

Additionally, its adaptability allows manufacturers to create complex designs without the need for extensive tooling changes. This flexibility not only saves money but also speeds up the time-to-market for new products.

Investing in repmold aligns with both financial goals and sustainability commitments. As industries increasingly prioritize greener solutions, this innovative material emerges as a clear winner.

Improved product quality and performance with repmold

Repmold transforms the manufacturing landscape by enhancing product quality and performance. This innovative material boasts superior consistency, minimizing defects that often plague traditional processes.

The unique properties of repmold allow for precise molding. As a result, manufacturers achieve tighter tolerances in their products. This precision translates into better fit and function across various applications.

Additionally, repmold offers increased durability. Items produced with this material withstand wear and tear more effectively than those made from conventional materials. The longevity of these products results in fewer replacements over time.

Moreover, the surface finish achieved with repmold is exceptional. It accommodates intricate designs while maintaining aesthetic appeal—a crucial factor for consumer satisfaction.

Manufacturers are realizing that using repmold not only elevates product standards but also enhances brand reputation in an increasingly competitive market.

Case studies of successful companies utilizing repmold in their production process

Several companies have embraced repmold, showcasing its transformative effects on their production lines. A leading automotive manufacturer integrated repmold in their component fabrication, reducing weight while enhancing durability. This change allowed for better fuel efficiency and lower emissions.

In the consumer electronics sector, a prominent tech giant utilized repmold to create intricate designs that traditional materials couldn’t achieve. The result? Sleeker products with improved thermal management capabilities.

Another case involved a furniture company adopting repmold for its innovative chair designs. By using this material, they achieved both sustainable sourcing and remarkable comfort without sacrificing style.

These examples illustrate how diverse industries leverage repmold to drive innovation and improve operational efficiency. Each success story emphasizes the versatility of repmold as it reshapes manufacturing possibilities across various fields.

Potential future developments and advancements in the use of repmold

The future of repmold in manufacturing is bright and full of potential. Advancements in material science may lead to even more versatile formulations, enhancing its properties further.

Research into biocompatible versions could open doors for applications in the medical field. This would allow manufacturers to utilize repmold for devices that require stringent safety standards.

Additionally, integrating smart technology with repmold processes can boost efficiency. Imagine sensors embedded within products, providing real-time data on performance.

Sustainability will likely drive innovation as well. As environmental concerns grow, eco-friendly formulations are expected to emerge, reducing carbon footprints significantly.

Collaboration between industries might also result in novel uses for repmold across sectors like aerospace or automotive. Such partnerships could redefine what’s possible with this adaptable material.

Conclusion:

Repmold has emerged as a game-changer in the manufacturing industry. Its unique properties offer numerous advantages over traditional materials, making it an attractive option for companies looking to innovate. The cost-effectiveness and sustainability of repmold not only benefit manufacturers but also contribute positively to the environment.

Moreover, companies that have adopted repmold report improved product quality and performance. This advancement can lead to significant competitive advantages in today’s fast-paced market. As more businesses recognize its potential, we may see further developments that push the boundaries of what is possible with this material.

You may also like

Exploring benzift78: The Next Big Thing in Tech Innovation

Qiser Explained: What You Need to Know for Your Next Project

Leave a Reply